What does the galvanizing process look like?

Hot-dip galvanizing involves immersion of steel components, which we want to protect from corrosion, in liquid zinc. The process begins with the preparation of the structure.

The next step is degreasing and cleaning the structure in pickling baths, and finally immersion in liquid zinc. The zinc then reaches every nook and cranny of the structure. Both outside and inside.

Why is zinc so effective in corrosion protection of steel?

Unlike other methods, such as painting, zinc reaches every part of the component. The fusion of zinc and steel results in a very hard and durable protective coating. The zinc coating is far more resistant to corrosion than ungalvanized steel. If it is damaged, the steel will still be protected from corrosion – this phenomenon is called cathodic protection.

How thick can the zinc layer be?

The thicknesses of the zinc layer depend on the thickness of the steel structure, the chemical composition of the steel and the length of time the component is immersed in the zinc bath. They usually range from 60 µm to 150 µm. For more on this topic, see "Coating thickness and types of steel".

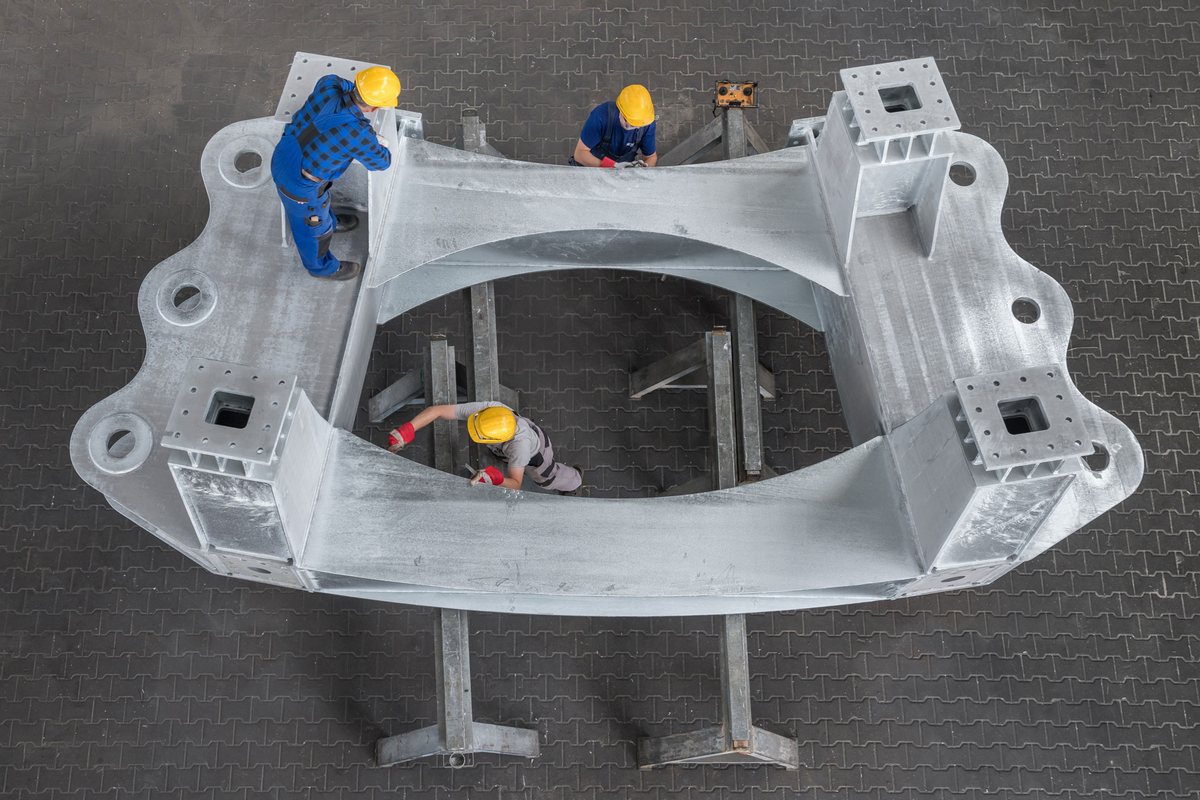

Low-temperature galvanizing is intended for larger and very large steel structures, reaching up to 21 meters (elements with a maximum length of 21 m, are galvanized in the Chrzanów branch of our galvanizing plant).

In the case of small elements, where their subsequent mutual fit is of great importance, it is worth using high-temperature galvanizing, which may include centrifugation of excess zinc. An offer of high-temperature galvanizing, also known as centrifugal galvanizing, is available in the galvanizing plant in Świdnica.

A good example of the use of the high-temperature method to protect steel are screws and nuts, which, because of the even coating, fit together and do not require subsequent threading, or machining.