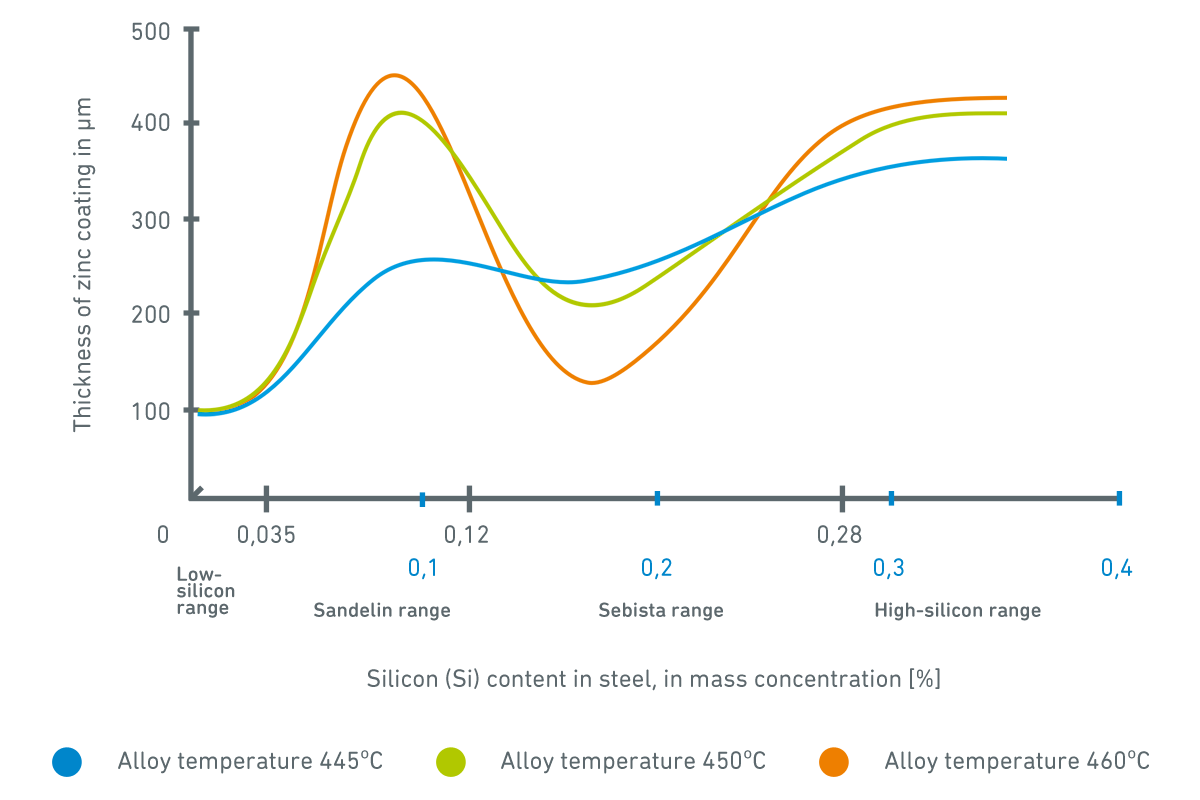

Graph – Thickness of the coatings obtained depending on the silicon content of the steel, with a constant immersion time of 10 minutes.

Steels containing less than 0.03% silicon (with Si + P ≤ 0.045%) and between 0.14% and 0.25% are best suited for galvanizing. The silicon and carbon content of the steel should not exceed 0.5% in total.

| Steel groups | Silicon content [%] | Appearance and thickness of the resulting zinc coating |

| Low-silicon | Up to 0.03 | Silvery, shiny, low thickness |

| Sandelin | From 0.03 to 0.14 | Grey, matt, rough, crumbly, "orange peel", very thick |

| Sebista | From 0.14 to 0.25 | Silver-glossy to matt grey, thickness dependent on immersion time |

| High-silicon | Above 0.25 | Matt, grey, crumbly, thick |