Ocynkownia Chrzanów

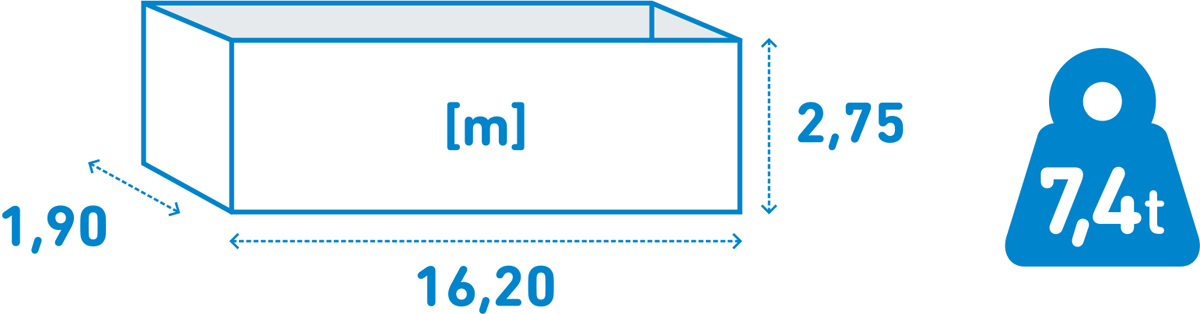

Zinc bath working dimensions:

16,20 lg. x 1,90 wd. x 2,75 dpt. [m], crane capacity: 7,4 t

At our plant in Chrzanów, we provide a specialised galvanizing service on so-called double-dipping, enabling galvanizing of components up to 21 m in length.

- Seppeler Ocynkownia Śląsk Sp. z o.o.

Zakład Chrzanów

ul. Kroczymiech 38

32-500 Chrzanów - +48 32 649 70 00

- chrzanow@ocynkownia.pl

- order form

- location website

Ocynkownia Kluczbork

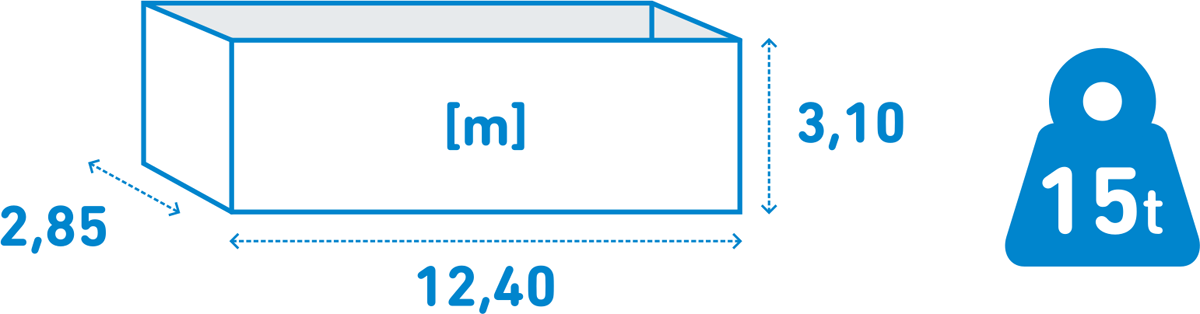

Zinc bath working dimensions:

12,40 lg. x 2,85 wd. x 3,10 dpt. [m], crane capacity: 15,0 t

Kluczbork is home to the widest galvanizing bath in Europe. Modern passivation of the zinc coating (cynklar) is also performed.

- Seppeler Ocynkownia Śląsk Sp. z o.o.

Zakład Kluczbork

ul. Przemysłowa 4

46-200 Kluczbork (Ligota Dolna) - +48 77 417 17 70

- kluczbork@ocynkownia.pl

- order form

- location website

Ocynkownia Częstochowa

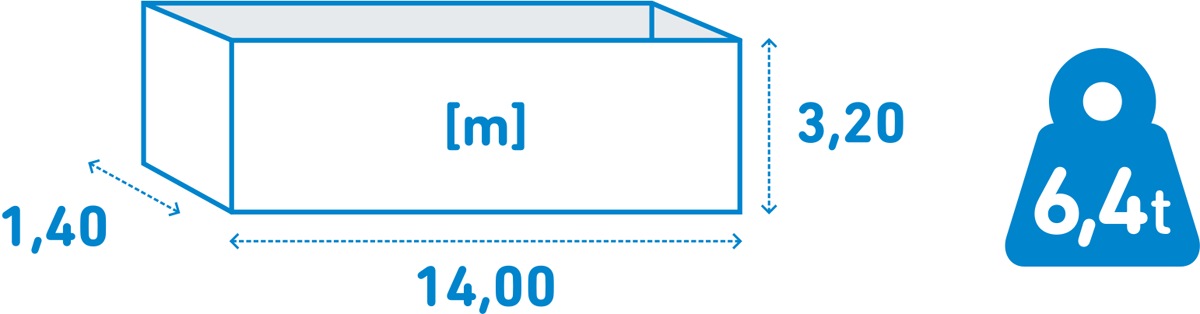

Zinc bath working dimensions:

14,00 lg. x 1,40 wd. x 3,20 dpt. [m], crane capacity: 6,4 t

The plant has the most modern and automated production line in Poland, allowing high repeatability of the set parameters to be achieved. A passivation service is also provided – cynklar.

- Seppeler Ocynkownia Śląsk Sp. z o.o.

Zakład Częstochowa

ul. Wojciecha Korfantego 29

42-202 Częstochowa - +48 34 367 60 00

- czestochowa@ocynkownia.pl

- order form

- location website

Ocynkownia Świdnica

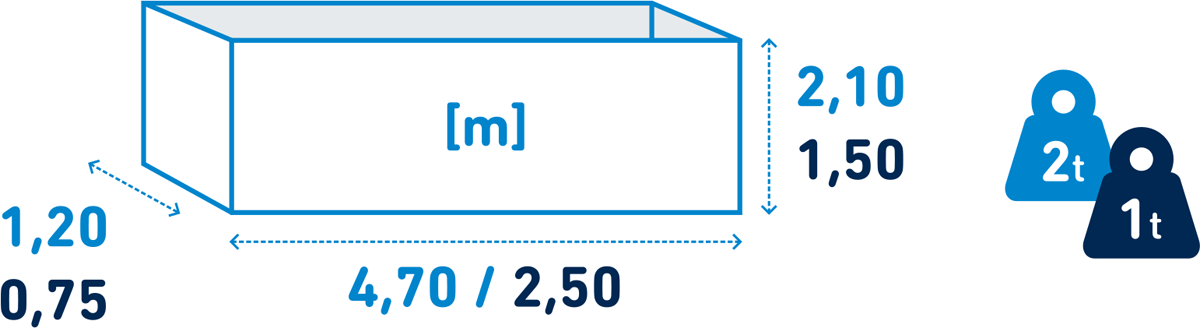

Zinc bath working dimensions:

4,70 lg. x 1,20 wd. x 2,10 dpt. [m], crane capacity: 2,0 t

High-temperature galvanizing:

2,50 lg. x 0,75 wd. x 1,50 dpt. [m], crane capacity: 1,0 t

Thanks to the use of a high-temperature bath, it is possible to accurately apply a zinc coating of 25 µm to 80 µm onto small components. This method is also known as centrifugal galvanization.

- Seppeler Ocynkownia Śląsk Sp. z o.o.

Zakład Świdnica

ul. Wokulskiego 14

58-100 Świdnica - +48 74 633 54 18

- swidnica@ocynkownia.pl

- order form

- location website