Metalworking

Galvanizing means no maintenance and no cyclical painting

Construction

Ability to protect structures from both inside and outside

Industry

Zinc coating retains its protective properties at high temperatures

Transport

Zinc coating is resistant to abrasion and other mechanical damage

Tourism

Zinc coating performs well in harsh weather conditions

Agriculture

Zinc coatings are certified by the PZH for contact with foodstuffs

Power industry

Thanks to large baths, galvanizing huge components is not a problem

Shipyards & maritime ind.

Hot-dip galvanizing effectively protects steel in extreme environments

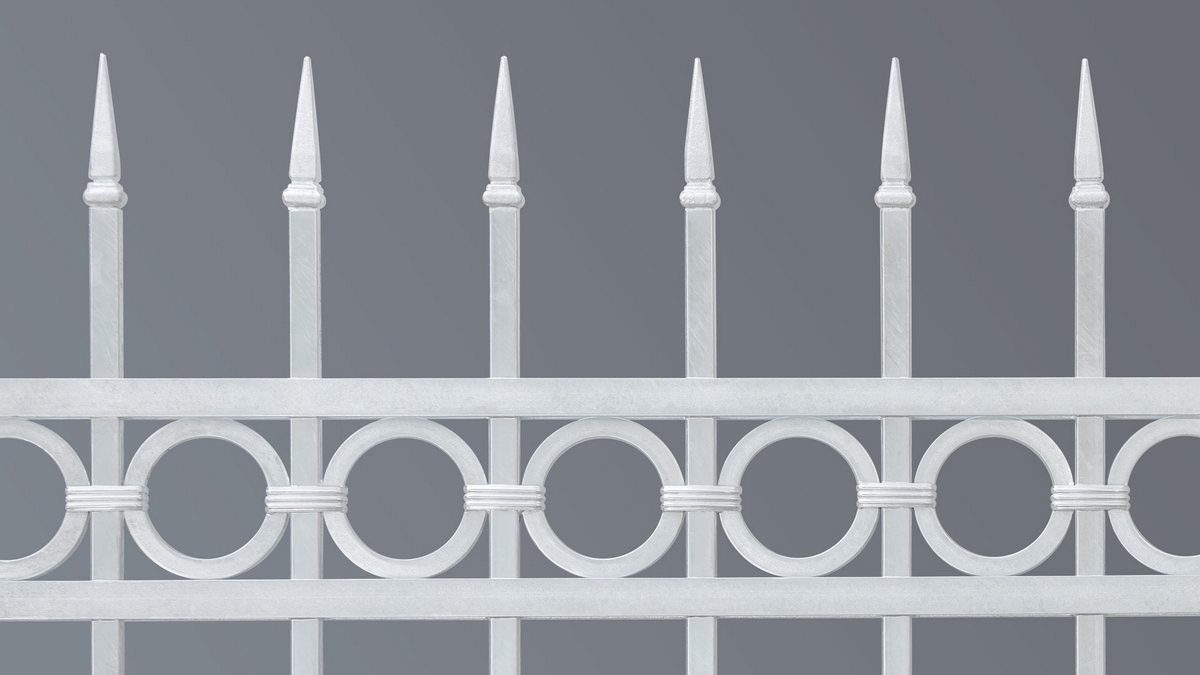

Zinc, which protects steel against corrosion, is the hardest and most resistant coating. Hence, it has been used for many years in transport and industry to coat steel railings, roadside posts, lamp posts, trailer frames and various types of tanks. Zinc is best able to withstand harsh winter conditions, salinisation from snow ploughing, and the harsh urban environment, where an enormous amount of chemical compounds from exhaust fumes and chimneys are deposited on railings and other elements.

With its modern passivation production line, our plant in Częstochowa enables galvanization with high parameter repeatability. This affects the ease of assembly of components. What is relevant, assembly usually takes place with screws and fasteners protected by high-temperature galvanizing. The service of high-precision centrifugal galvanizing is provided by the galvanizing plant in Świdnica.

The maintenance-free nature of zinc coatings means that there is no need for cyclical maintenance as in case of paint. Painting hundreds of metres of fence every few years is neither economical nor fully effective, as confirmed by ironworkers. The advantage of galvanizing has been recognised particularly in agriculture, where it would be difficult to maintain huge grain silos or massive fertiliser tanks, which are galvanized at our galvanizing plant in Kluczbork, in the widest galvanizing bath in Europe. It is also difficult to imagine the maintenance of the paint coating on a suspended tourist footbridge (even one such as SkyBridge 721).

Zinc is also applied in the power industry. The old painted high-voltage poles look unattractive and in recent years have been replaced by galvanized tubular poles. Wind farms situated both onshore and offshore also base their construction on galvanized tubular poles. The technology we offer is widely used in construction, where the basis of the structure is steel (e.g. in multi-storey garages or warehouse halls). Thanks to one of the longest galvanizing baths in Poland, available in our galvanizing plant in Chrzanów, which galvanizes constructions as long as 21 metres, we can protect such huge elements against rust for many decades.